A Complete Information to Valve Varieties: A Visible and Explanatory Chart

Associated Articles: A Complete Information to Valve Varieties: A Visible and Explanatory Chart

Introduction

With enthusiasm, let’s navigate by the intriguing subject associated to A Complete Information to Valve Varieties: A Visible and Explanatory Chart. Let’s weave fascinating info and provide recent views to the readers.

Desk of Content material

A Complete Information to Valve Varieties: A Visible and Explanatory Chart

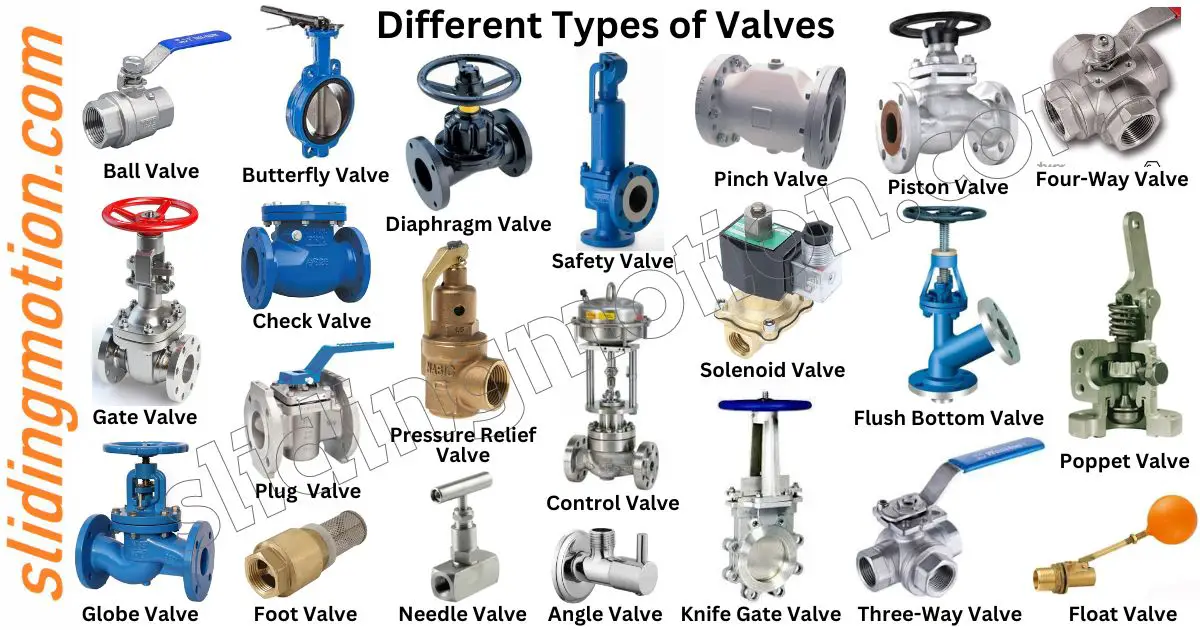

Valves are ubiquitous parts in numerous industrial, business, and residential functions. Their operate is straightforward – to regulate the move of fluids (liquids, gases, or slurries) – however the range of their designs displays the huge array of functions and working circumstances they encounter. Understanding the various kinds of valves is essential for engineers, technicians, and anybody working with fluid techniques. This text supplies an in depth overview of varied valve sorts, introduced alongside a visible chart for simple reference, enabling a complete understanding of their functionalities and functions.

I. Classification of Valves: A Multifaceted Strategy

Valves might be categorised in a number of methods, relying on the standards used. The commonest classifications embrace:

-

By Move Management Mechanism: This categorizes valves based mostly on how they regulate fluid move. Examples embrace gate valves (on/off), globe valves (throttling), ball valves (on/off or throttling), and butterfly valves (on/off or throttling).

-

By Valve Physique Development: This refers back to the bodily design and materials of the valve physique. Examples embrace cast valves (excessive strain), forged valves (normal function), and welded valves (specialised functions).

-

By Actuator Kind: This categorizes valves based mostly on how they’re operated. Examples embrace guide valves (handwheel, lever), pneumatic valves (compressed air), electrical valves (motor), and hydraulic valves (hydraulic strain).

-

By Utility: This classification focuses on the particular business or course of the place the valve is used. Examples embrace valves for water therapy, oil and gasoline, chemical processing, and HVAC techniques.

II. Key Valve Varieties: A Detailed Exploration

The next sections delve into the specifics of frequent valve sorts, highlighting their options, benefits, and limitations. The accompanying chart will visually symbolize these options.

(A) Linear Movement Valves:

-

Globe Valves: These valves use a disc that strikes linearly to impede or permit fluid move. They provide glorious throttling capabilities, permitting for exact move management. Nevertheless, they’ve greater strain drop than different valves because of the move restriction. Appropriate for functions requiring exact move regulation and on/off management.

-

Gate Valves: These valves make the most of a gate that strikes perpendicularly to the move path, creating a very unobstructed move when open. Primarily used for on/off service, they aren’t splendid for throttling because of the potential for erosion and put on. Greatest suited to high-pressure, large-diameter pipelines the place minimal strain drop is desired.

-

Needle Valves: Much like globe valves, however with a a lot smaller and extra exactly tapered needle-shaped plug. They supply extraordinarily nice move management, making them splendid for exact metering and regulation of small flows. Typically utilized in instrumentation and analytical functions.

(B) Rotary Movement Valves:

-

Ball Valves: These valves make the most of a spherical ball with a gap bored by its heart. Rotating the ball opens or closes the move path. They provide glorious on/off service, comparatively compact design, and are simply automated. They’re much less appropriate for exact throttling. Broadly utilized in varied functions resulting from their simplicity and reliability.

-

Butterfly Valves: These valves make the most of a disc that rotates round a central axis. They’re compact and light-weight, providing good on/off service and a few throttling capabilities. Nevertheless, they might exhibit greater strain drop than ball valves on the similar move price. Typically utilized in giant diameter pipelines and functions the place house is proscribed.

-

Plug Valves: These valves make the most of a cylindrical or tapered plug that rotates to regulate move. They provide good on/off service and are comparatively compact. Some sorts permit for multi-port configurations. They’re much less appropriate for throttling and could also be liable to leakage if not correctly maintained.

(C) Specialised Valves:

-

Test Valves: These valves routinely forestall reverse move. They’re passive units that open within the course of move and shut routinely when the move reverses. Important for stopping backflow in pump techniques and pipelines. Varied sorts exist, together with swing test valves, carry test valves, and ball test valves.

-

Diaphragm Valves: These valves use a versatile diaphragm to regulate move. They’re appropriate for functions involving corrosive or viscous fluids, because the diaphragm isolates the inner valve mechanism from the fluid. They provide good throttling and on/off capabilities.

-

Security Aid Valves (PRV): These valves routinely open to alleviate extra strain in a system, stopping harm or explosions. They’re essential security units in strain vessels and pipelines. They’re designed to open at a selected strain setpoint and shut as soon as the strain drops beneath a sure stage.

-

Management Valves: These valves are used for exact regulation of fluid move based mostly on a management sign. They’re typically built-in into automated techniques and are essential for sustaining course of parameters. Varied sorts exist, together with proportional, integral, and spinoff (PID) management valves.

(D) Valve Supplies and Development:

The selection of fabric for valve development relies upon closely on the appliance. Frequent supplies embrace:

- Metal: Excessive energy and sturdiness, appropriate for high-pressure functions.

- Stainless Metal: Corrosion resistance, appropriate for chemical processing and corrosive fluids.

- Forged Iron: Value-effective, appropriate for low-pressure functions.

- Brass: Corrosion resistance, appropriate for potable water functions.

- Plastic: Light-weight and corrosion-resistant, appropriate for sure chemical and low-pressure functions.

III. Valve Choice Standards:

Selecting the best valve requires cautious consideration of a number of components:

- Fluid Properties: Viscosity, temperature, strain, corrosiveness.

- Move Fee and Stress: The valve should be sized appropriately for the required move and strain.

- Working Circumstances: Temperature, strain fluctuations, and environmental components.

- Upkeep Necessities: Ease of upkeep and accessibility.

- Value: Balancing value with efficiency and reliability.

- Automation Necessities: Guide, pneumatic, electrical, or hydraulic actuation.

IV. Valve Chart (Illustrative):

(Please be aware: A complete visible chart could be included right here, illustrating the totally different valve sorts, their development, and their working mechanisms. Because of the limitations of this text-based format, an in depth visible illustration can’t be offered. Nevertheless, a simplified desk summarizing key options is introduced beneath.)

| Valve Kind | Move Management | Actuator Varieties | Stress Ranking | Throttling Functionality | Purposes | Benefits | Disadvantages |

|---|---|---|---|---|---|---|---|

| Globe Valve | Linear | Guide, Pneumatic, Electrical | Varies | Wonderful | Exact move regulation, on/off management | Exact management, extensively out there | Excessive strain drop, much less environment friendly than gate valves |

| Gate Valve | Linear | Guide, Pneumatic, Electrical | Varies | Poor | On/off service, high-pressure pipelines | Minimal strain drop when totally open | Not appropriate for throttling |

| Ball Valve | Rotary | Guide, Pneumatic, Electrical | Varies | Reasonable | On/off service, normal function | Compact, dependable, simple to automate | Much less exact throttling |

| Butterfly Valve | Rotary | Guide, Pneumatic, Electrical | Varies | Reasonable | Giant diameter pipelines, space-constrained | Compact, light-weight | Increased strain drop than ball valves at similar move |

| Test Valve | Passive | N/A | Varies | N/A | Stopping backflow | Easy, dependable | Restricted move management |

| Diaphragm Valve | Linear | Guide, Pneumatic, Electrical | Varies | Good | Corrosive fluids, viscous fluids | Protects inside parts from fluid | May be slower than different valve sorts |

V. Conclusion:

Choosing the suitable valve for a selected utility is a vital side of fluid system design. An intensive understanding of the assorted valve sorts, their operational ideas, and their limitations is important for engineers and technicians. This text, together with a complete visible chart (which might ideally accompany this textual content), supplies a basis for knowledgeable decision-making in valve choice, making certain optimum system efficiency, security, and effectivity. Bear in mind to at all times seek the advice of producer specs and related business requirements when choosing and putting in valves.

Closure

Thus, we hope this text has offered invaluable insights into A Complete Information to Valve Varieties: A Visible and Explanatory Chart. We thanks for taking the time to learn this text. See you in our subsequent article!