Decoding the Dimensions: A Complete Information to Eye Bolt Sizes and Functions

Associated Articles: Decoding the Dimensions: A Complete Information to Eye Bolt Sizes and Functions

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to Decoding the Dimensions: A Complete Information to Eye Bolt Sizes and Functions. Let’s weave attention-grabbing info and provide recent views to the readers.

Desk of Content material

Decoding the Dimensions: A Complete Information to Eye Bolt Sizes and Functions

Eye bolts, these seemingly easy fasteners with a threaded shank and a round eye on the prime, play a vital function in numerous industries, from building and rigging to manufacturing and marine purposes. Their seemingly simple design belies a stunning complexity in sizing and choice, essential for making certain security and structural integrity. This text supplies a complete information to understanding eye bolt sizes, their specs, and the essential elements to contemplate when choosing the proper one in your utility.

Understanding Eye Bolt Specs:

Earlier than diving right into a chart of eye bolt sizes, it is important to know the important thing specs used to outline them. These specs are important for choosing the suitable eye bolt for a given load and utility. Crucial parameters embody:

-

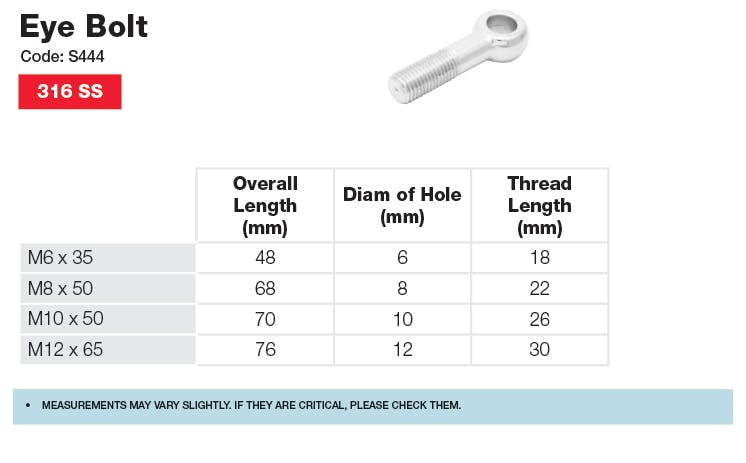

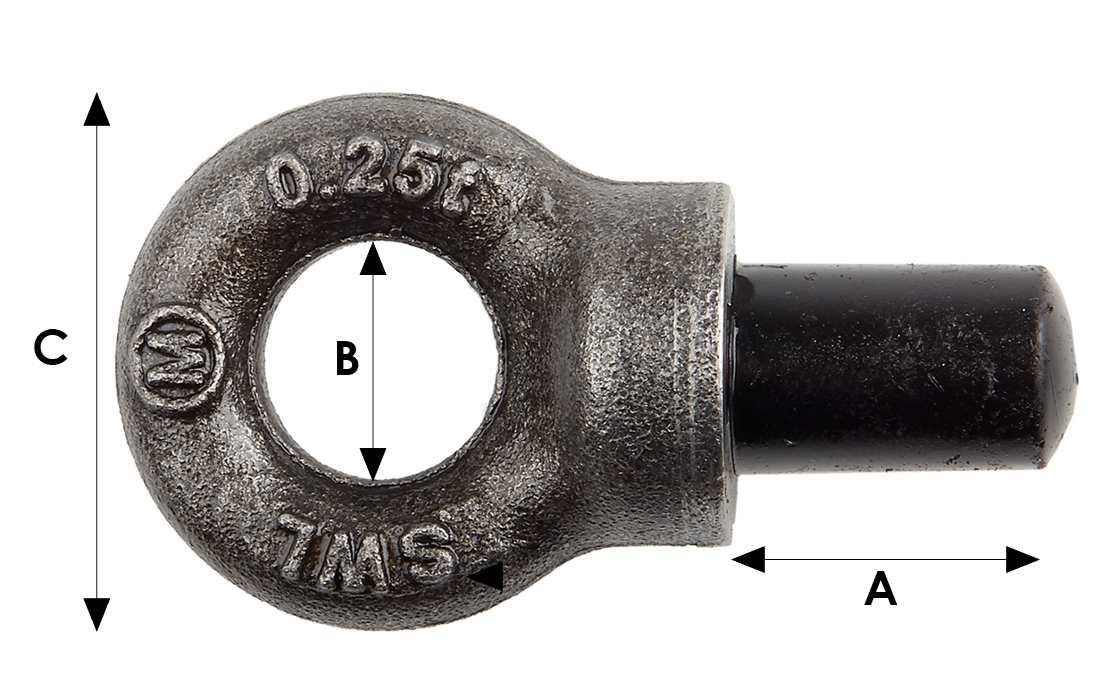

Diameter (d): This refers back to the diameter of the threaded shank of the attention bolt. It is often expressed in inches or millimeters and immediately correlates to the bolt’s power and load-bearing capability. Bigger diameters point out higher power.

-

Eye Diameter (D): That is the diameter of the round eye on the prime of the bolt. It determines the dimensions of the shackle, ring, or different becoming that may be hooked up. The attention diameter needs to be appropriately sized to accommodate the connecting {hardware} with out undue stress.

-

Thread Dimension and Sort: Eye bolts can be found with numerous thread sizes and kinds, equivalent to UNC (Unified Nationwide Coarse), UNF (Unified Nationwide High quality), and metric threads. The thread dimension is essential for making certain a safe reference to the mating nut.

-

Size (L): That is the general size of the attention bolt, from the underside of the shank to the highest of the attention. The size is essential for figuring out the quantity of thread engagement and total utility suitability. Inadequate size can result in inadequate thread engagement and lowered power.

-

Materials: Eye bolts are sometimes constructed from supplies like metal (carbon metal, alloy metal, chrome steel), brass, or different metals. The fabric alternative dictates the bolt’s power, corrosion resistance, and suitability for particular environments. Chrome steel eye bolts, for instance, provide superior corrosion resistance in comparison with carbon metal.

-

Working Load Restrict (WLL): That is the utmost load that an eye fixed bolt can safely assist below regular working circumstances. The WLL is essential for making certain security and may by no means be exceeded. Producers present WLL rankings based mostly on testing and materials specs. It’s essential to notice that the WLL is considerably lower than the final word tensile power.

-

Security Issue: A security issue is integrated into the WLL to account for unexpected circumstances, materials variations, and potential misuse. This issue ensures that the attention bolt has a substantial margin of security even below surprising stress.

Eye Bolt Sizes Chart (Illustrative):

The next chart supplies a common overview of eye bolt sizes. It’s essential to know that this isn’t an exhaustive checklist and particular dimensions and WLLs will fluctuate based mostly on the producer, materials, and thread kind. At all times seek advice from the producer’s specs for correct information.

| Diameter (d) (inches) | Eye Diameter (D) (inches) | Approximate Size (L) (inches) | Materials Instance | Approximate WLL (lbs) | Thread Sort Instance |

|---|---|---|---|---|---|

| 1/4 | 3/8 | 1 | Carbon Metal | 700 | UNC |

| 3/8 | 1/2 | 1.5 | Stainless Metal | 1500 | UNC |

| 1/2 | 5/8 | 2 | Carbon Metal | 3000 | UNC |

| 5/8 | 3/4 | 2.5 | Stainless Metal | 6000 | UNC |

| 3/4 | 7/8 | 3 | Carbon Metal | 10000 | UNC |

| 7/8 | 1 | 3.5 | Alloy Metal | 15000 | UNC |

| 1 | 1 1/4 | 4 | Carbon Metal | 20000 | UNC |

| 1 1/4 | 1 1/2 | 4.5 | Stainless Metal | 30000 | UNC |

| 1 1/2 | 1 3/4 | 5 | Alloy Metal | 45000 | UNC |

Notice: This chart supplies approximate values. Precise dimensions and WLLs can fluctuate considerably relying on the producer and particular eye bolt design. At all times seek the advice of the producer’s information sheet for exact specs. Metric equivalents are additionally broadly out there.

Elements Affecting Eye Bolt Choice:

Selecting the right eye bolt includes contemplating a number of essential elements:

-

Load Necessities: That is probably the most essential issue. The chosen eye bolt should have a WLL considerably greater than the anticipated load to make sure a ample security margin. By no means exceed the WLL.

-

Utility: Totally different purposes have completely different necessities. Rigging purposes, as an illustration, demand eye bolts with greater power and corrosion resistance in comparison with these utilized in much less demanding environments.

-

Environmental Circumstances: Publicity to harsh environments like saltwater or chemical compounds necessitates the usage of corrosion-resistant supplies like chrome steel.

-

Set up Technique: The strategy of set up influences the selection of eye bolt size and thread kind. Guarantee ample thread engagement for safe fastening.

-

Connecting {Hardware}: The scale of the attention needs to be suitable with the connecting {hardware}, equivalent to shackles, rings, or hooks. Guarantee a correct match to keep away from stress concentrations.

-

Materials Compatibility: Take into account the compatibility of the attention bolt materials with the supplies of the encompassing elements to stop corrosion or different antagonistic reactions.

Security Precautions:

-

Examine Eye Bolts Repeatedly: Common inspection for injury, put on, or corrosion is essential. Broken eye bolts needs to be changed instantly.

-

By no means Exceed WLL: Working an eye fixed bolt past its WLL can result in catastrophic failure.

-

Correct Set up: Guarantee right set up to stop untimely failure or harm.

-

Use Applicable Instruments: Use the right instruments for set up to keep away from damaging the attention bolt or the encompassing elements.

-

Comply with Producer’s Directions: At all times observe the producer’s directions for set up, use, and upkeep.

Conclusion:

Deciding on the suitable eye bolt is essential for making certain security and structural integrity in numerous purposes. This text supplies a foundational understanding of eye bolt sizes and specs. Nevertheless, it is essential to do not forget that this info is for steerage solely. At all times seek the advice of the producer’s information sheets, related business requirements (equivalent to ASME B18.23), and certified engineering professionals to find out the right eye bolt in your particular wants. Ignoring these tips can result in critical penalties, together with tools failure and potential harm. Prioritize security and all the time select an eye fixed bolt with a considerably greater WLL than the anticipated load. Bear in mind, the best alternative can imply the distinction between a profitable mission and a catastrophic failure.

Closure

Thus, we hope this text has offered invaluable insights into Decoding the Dimensions: A Complete Information to Eye Bolt Sizes and Functions. We recognize your consideration to our article. See you in our subsequent article!