Decoding the Dimensions: A Complete Information to Spiral Wound Gasket Charts

Associated Articles: Decoding the Dimensions: A Complete Information to Spiral Wound Gasket Charts

Introduction

With enthusiasm, let’s navigate by way of the intriguing matter associated to Decoding the Dimensions: A Complete Information to Spiral Wound Gasket Charts. Let’s weave fascinating info and supply recent views to the readers.

Desk of Content material

Decoding the Dimensions: A Complete Information to Spiral Wound Gasket Charts

Spiral wound gaskets are ubiquitous in industrial functions, offering dependable sealing options for a variety of pressures and temperatures. Understanding their dimensions is essential for correct choice and set up, guaranteeing leak-free operation and stopping pricey downtime. This text delves into the intricacies of spiral wound gasket dimension charts, explaining the varied parameters, their significance, and the way to successfully interpret them.

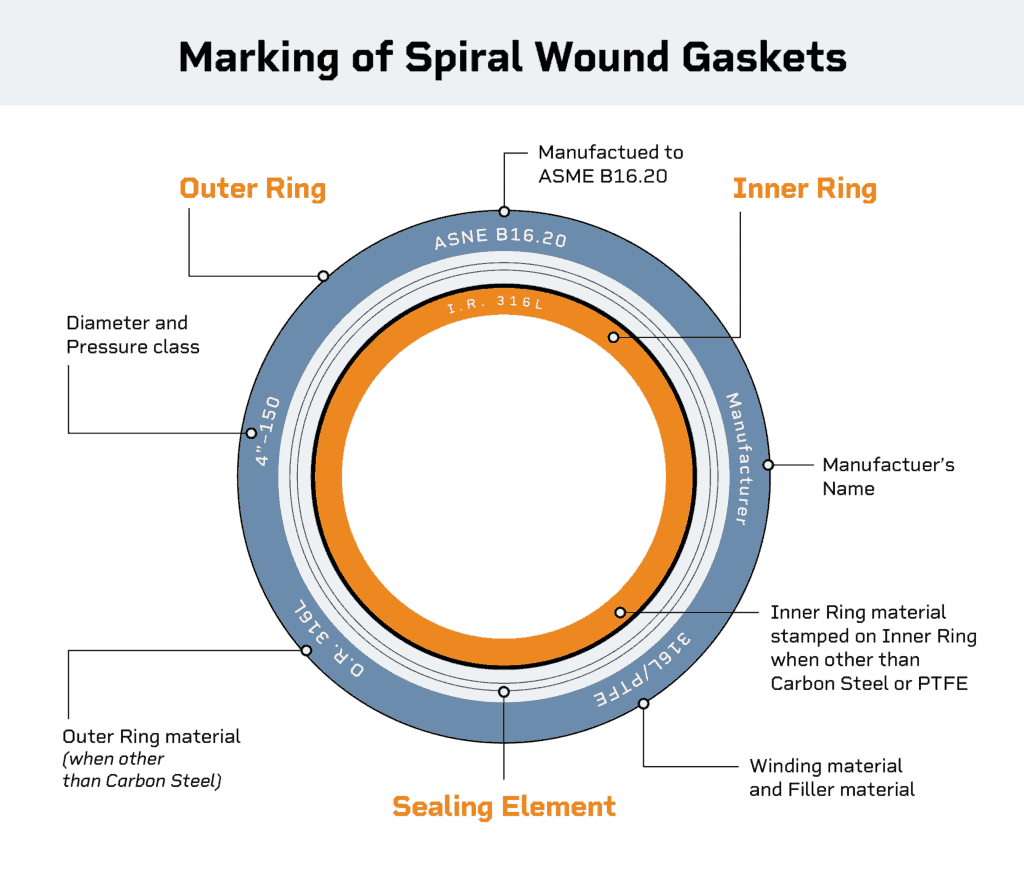

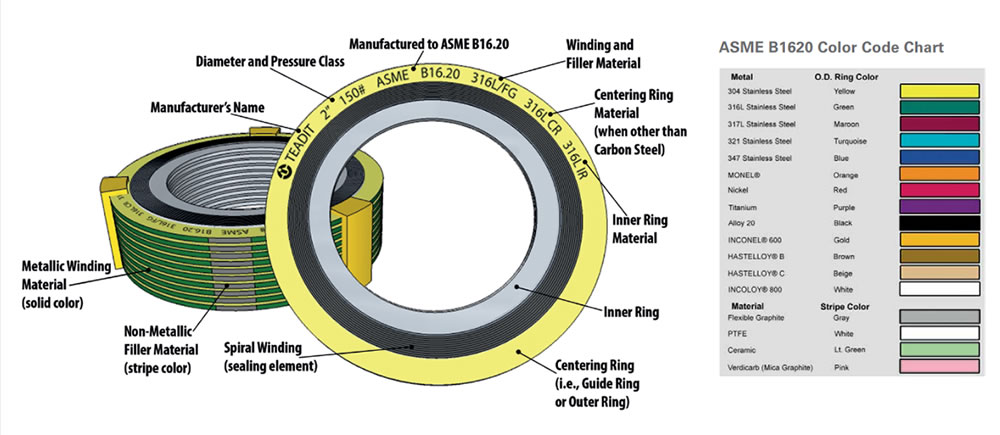

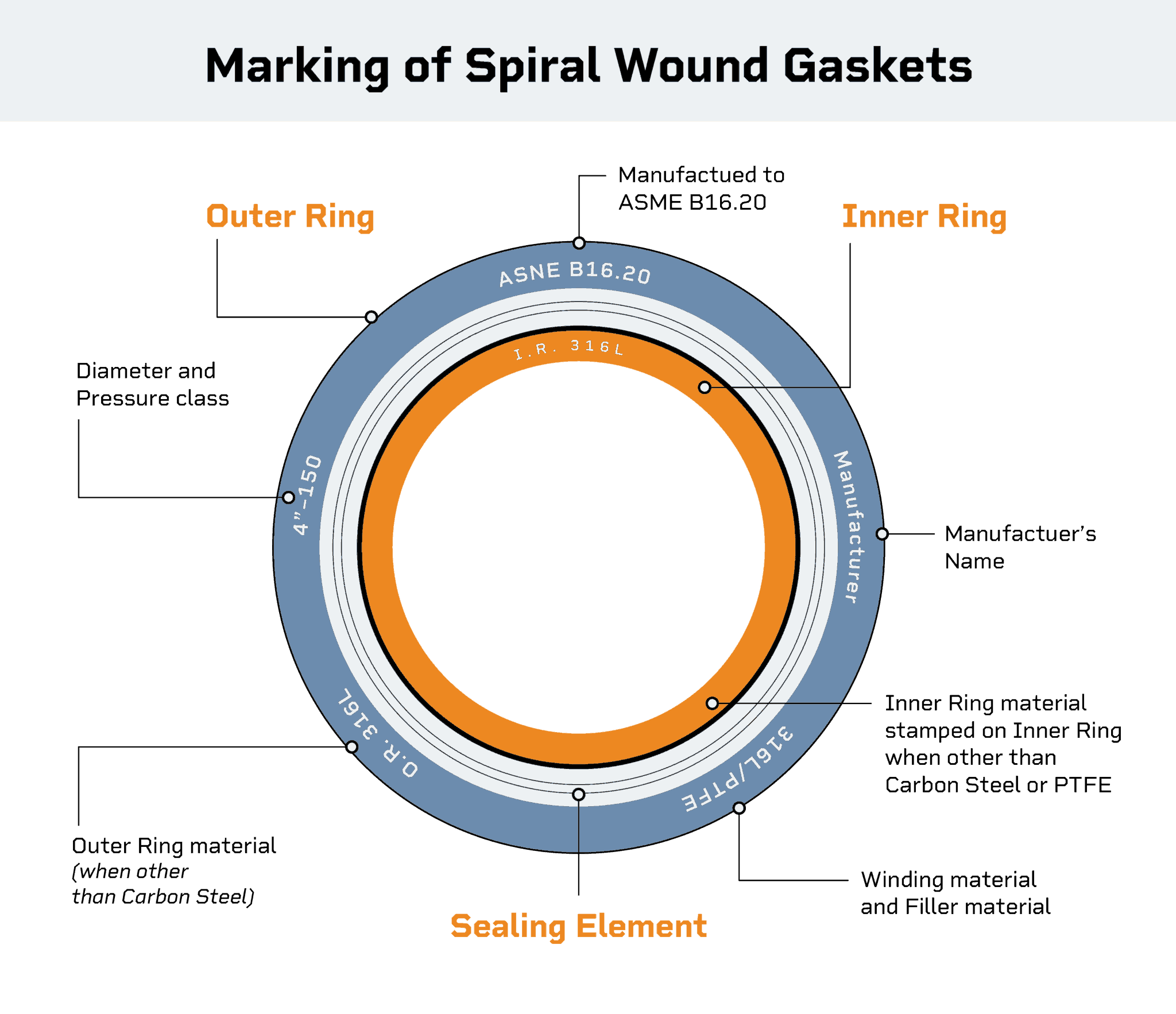

Understanding Spiral Wound Gasket Building

Earlier than diving into the charts, let’s briefly evaluation the development of a spiral wound gasket. These gaskets are composed of a versatile filler materials, sometimes graphite or PTFE, sandwiched between layers of metallic (sometimes stainless-steel, however different supplies like Monel or Inconel are additionally used). This composite materials is wound in a steady spiral, making a resilient and adaptable seal. The outer and interior diameters, together with the thickness, decide the gasket’s general dimensions and sealing capabilities.

Key Dimensions in Spiral Wound Gasket Charts

A typical spiral wound gasket dimension chart will embrace the next parameters:

-

Inside Diameter (ID): That is the diameter of the interior gap of the gasket. It needs to be barely smaller than the bolt circle diameter (BCD) of the flange to permit for correct centering and compression. An improperly sized ID can result in uneven compression and leakage.

-

Exterior Diameter (OD): That is the diameter of the outer fringe of the gasket. The OD is essential for guaranteeing the gasket suits inside the flange’s confines. Too small, and the gasket will not cowl the whole flange face; too giant, and it could intervene with adjoining parts.

-

Thickness (T): The thickness of the gasket is a crucial parameter influencing its compressive energy and sealing effectiveness. Thicker gaskets usually present higher sealing at increased pressures, however extreme thickness can result in bolt stress points. The thickness is often specified on the gasket’s heart.

-

Nominal Dimension: This usually refers back to the pipe dimension or flange dimension the gasket is designed for. Whereas not a direct dimensional measurement, it is essential for choosing the right gasket for a selected utility. It helps guarantee compatibility with the flange and bolt sample.

-

Materials: The chart will specify the supplies used for each the filler and the metallic winding. This info is essential for chemical compatibility and temperature resistance. Completely different supplies have completely different compression traits and suitability for numerous fluids and environments.

-

Kind: Some charts might categorize gaskets based mostly on their sort, comparable to full-face, ring-type, or inside-outside sort, every having barely completely different dimensional issues.

-

Model: Sure gaskets might have particular design options, comparable to a centering ring or a unique winding sample, which might be mirrored within the chart. These particulars have an effect on the general dimensions and sealing efficiency.

Deciphering the Chart: A Step-by-Step Information

Spiral wound gasket dimension charts are sometimes offered in tabular format. To successfully use them, observe these steps:

-

Establish the Flange Kind and Dimension: Decide the kind of flange (e.g., ASME B16.5, ANSI B16.47) and its nominal dimension. That is the place to begin for choosing the suitable gasket.

-

Find the Related Part: The chart will possible be organized by flange sort and dimension. Discover the part comparable to your flange.

-

Choose the Desired Materials: Select the filler and metallic winding supplies based mostly on the applying’s necessities, contemplating elements like temperature, stress, and chemical compatibility.

-

Establish the Related Dimensions: After getting situated the right part and materials, the chart will present the ID, OD, and thickness for that particular gasket.

-

Confirm Compatibility: Double-check that the gasket’s ID is barely smaller than the flange’s BCD and that the OD is appropriate for the flange’s dimensions.

-

Think about the Strain and Temperature: Whereas the chart gives dimensions, it is essential to seek the advice of the producer’s specs to make sure the chosen gasket can face up to the working stress and temperature.

Past the Fundamentals: Superior Concerns

A number of different elements affect gasket choice past the essential dimensions:

-

Floor End: The floor end of the flanges considerably impacts sealing efficiency. Tough surfaces might require thicker gaskets or specialised supplies.

-

Bolt Load: The proper bolt load is important for reaching correct gasket compression. Inadequate compression can result in leaks, whereas extreme compression can harm the gasket or the flange.

-

Gasket Stress: Extreme gasket stress can result in untimely failure. Correct gasket choice and bolt tightening procedures are essential to keep away from this.

-

Particular Purposes: For distinctive functions, comparable to cryogenic or high-vacuum environments, specialised gasket supplies and designs could also be mandatory, and the dimension chart needs to be consulted accordingly.

-

Producer’s Specs: All the time confer with the producer’s particular directions and proposals for the chosen gasket. These directions usually include essential info past what’s present in a normal dimension chart.

Examples of Dimension Chart Knowledge:

Whereas a full chart can’t be reproduced right here on account of area constraints, a pattern of knowledge may appear to be this:

| Nominal Dimension | ID (mm) | OD (mm) | Thickness (mm) | Materials |

|---|---|---|---|---|

| 2" (ASME B16.5) | 50 | 100 | 3 | 316SS/Graphite |

| 4" (ASME B16.5) | 100 | 150 | 4 | 316SS/Graphite |

| 6" (ASME B16.5) | 150 | 200 | 5 | 316SS/PTFE |

It is a simplified instance; precise charts are way more intensive and embrace quite a few variations in dimension, materials, and magnificence.

Conclusion:

Spiral wound gasket dimension charts are indispensable instruments for engineers and technicians concerned in industrial sealing functions. Understanding the parameters, decoding the info, and contemplating the varied elements affecting gasket choice are essential for guaranteeing dependable and leak-free operation. By fastidiously reviewing the chart and consulting the producer’s specs, you may choose the suitable gasket to fulfill the particular calls for of your utility, minimizing downtime and maximizing effectivity. Bear in mind to all the time prioritize security and cling to finest practices for gasket set up and upkeep.

.png)

Closure

Thus, we hope this text has supplied beneficial insights into Decoding the Dimensions: A Complete Information to Spiral Wound Gasket Charts. We thanks for taking the time to learn this text. See you in our subsequent article!