Decoding the Drive: A Complete Information to Motor Sorts and Their Purposes

Associated Articles: Decoding the Drive: A Complete Information to Motor Sorts and Their Purposes

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the Drive: A Complete Information to Motor Sorts and Their Purposes. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Decoding the Drive: A Complete Information to Motor Sorts and Their Purposes

Electrical motors are the unsung heroes of recent life, powering all the pieces from our smartphones and electrical automobiles to industrial equipment and robotic methods. Understanding the varied panorama of motor sorts is essential for engineers, technicians, and anybody searching for to optimize effectivity, efficiency, and cost-effectiveness in functions requiring rotary movement. This text supplies a complete information to varied motor sorts, detailing their traits, functions, and comparative benefits and downsides. We’ll manage this exploration utilizing a conceptual chart framework, permitting for straightforward comparability and understanding.

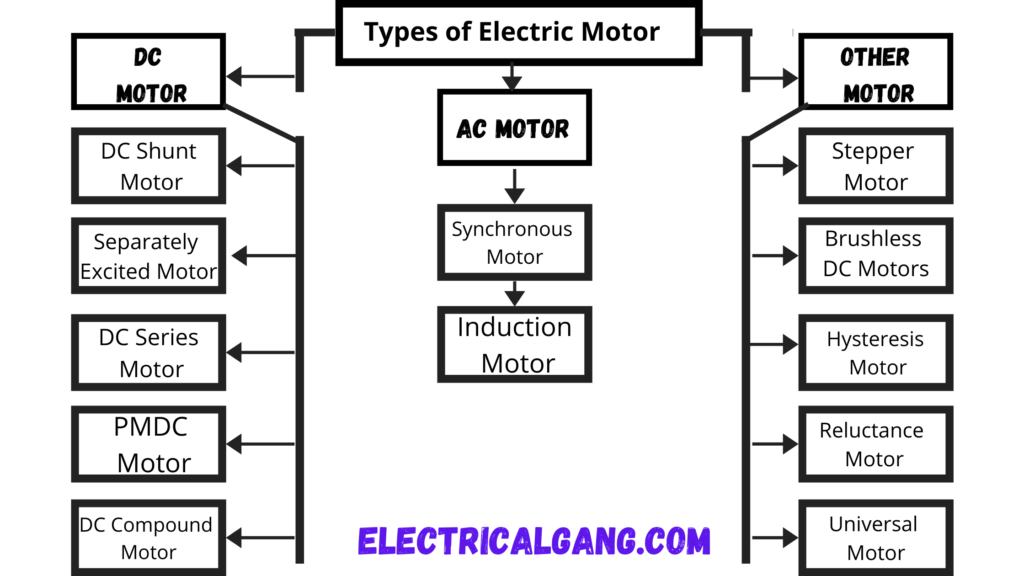

I. A Conceptual Chart of Motor Sorts:

The next chart categorizes electrical motors based mostly on a number of key traits: energy supply, building, and working rules. This isn’t exhaustive, as quite a few variations and hybrid designs exist, but it surely supplies a powerful basis for understanding the broader panorama.

| Motor Sort | Energy Supply | Building | Working Precept | Benefits | Disadvantages | Typical Purposes |

|---|---|---|---|---|---|---|

| DC Brushed Motor | DC | Commutator, Brushes | Magnetic discipline interplay between rotor and stator | Easy, cheap, good velocity management | Requires upkeep (brush substitute), decrease effectivity, sparking | Toys, small home equipment, energy instruments (older fashions) |

| DC Brushless Motor | DC | Everlasting magnets, digital commutation | Magnetic discipline interplay between rotor and stator, managed electronically | Excessive effectivity, lengthy lifespan, exact velocity management | Increased preliminary price, requires digital controller | Drones, electrical automobiles, robotics, high-performance functions |

| AC Induction Motor (Asynchronous) | AC | Stator windings, rotor bars (squirrel cage or wound rotor) | Rotating magnetic discipline induces present in rotor, creating torque | Sturdy, easy, low upkeep, cost-effective | Decrease effectivity than synchronous motors, much less exact velocity management | Followers, pumps, compressors, industrial equipment |

| AC Synchronous Motor | AC | Stator windings, everlasting magnets or wound rotor | Rotor synchronizes with rotating magnetic discipline of stator | Excessive effectivity, exact velocity management, excessive energy issue | Extra advanced, requires exact excitation management, could also be much less strong than induction motors | Excessive-precision functions, servo methods, clocks, electrical energy technology |

| Stepper Motor | DC or AC | Everlasting magnets or electromagnets | Rotates in discrete steps, managed by pulses | Exact positioning, excessive holding torque, easy management | Comparatively low velocity, restricted torque at increased speeds | Printers, CNC machines, robotics, positioning methods |

| Servo Motor | DC or AC (usually brushless DC) | Numerous configurations | Exact management of velocity and place by way of suggestions mechanism | Excessive accuracy, quick response, wonderful management | Increased price, requires suggestions system | Robotics, industrial automation, precision equipment |

| Linear Motor | DC or AC | Linear stator and mover | Linear movement straight, with out gears or belts | Excessive velocity, excessive acceleration, no mechanical transmission losses | Increased price, requires specialised design | Excessive-speed transportation, industrial automation, magnetic levitation trains |

| Common Motor | AC or DC | Commutator, brushes | Operates on each AC and DC energy | Can obtain excessive speeds, comparatively cheap | Requires upkeep, decrease effectivity, sparking | Energy instruments, vacuum cleaners, blenders |

II. Detailed Exploration of Motor Sorts:

Let’s delve deeper into the traits and functions of some key motor sorts:

A. DC Motors:

-

DC Brushed Motors: These motors are the best and traditionally most typical sort of DC motor. Their simplicity interprets to decrease price, however the mechanical commutator and brushes are vulnerable to put on and tear, limiting their lifespan and effectivity. The sparking related to the commutator can be an issue in some functions.

-

DC Brushless Motors: These motors overcome the constraints of brushed DC motors by changing the mechanical commutator with digital commutation. This leads to considerably improved effectivity, longer lifespan, and quieter operation. Nevertheless, they require a extra advanced digital controller, growing the preliminary price. Their excessive effectivity and exact management make them superb for functions demanding excessive efficiency and reliability.

B. AC Motors:

-

AC Induction Motors: These are the workhorses of trade, famend for his or her robustness, simplicity, and low upkeep necessities. They’re asynchronous, that means the rotor velocity is barely lower than the synchronous velocity of the rotating magnetic discipline. This inherent slip attribute could be advantageous in some functions, but it surely additionally limits their velocity management precision. Squirrel-cage induction motors are the commonest sort, providing a easy, strong design, whereas wound-rotor induction motors enable for higher velocity management however are extra advanced.

-

AC Synchronous Motors: These motors obtain synchronous velocity, that means the rotor rotates on the identical velocity because the rotating magnetic discipline. This leads to increased effectivity and extra exact velocity management in comparison with induction motors. They are often additional categorized into everlasting magnet synchronous motors (PMSM) and wound rotor synchronous motors. PMSMs are more and more well-liked as a result of their excessive effectivity and easy building.

C. Specialised Motors:

-

Stepper Motors: These motors provide exact management over rotational place, transferring in discrete steps. They are perfect for functions requiring exact positioning, resembling 3D printers and CNC machines. Nevertheless, their velocity is proscribed, and torque decreases at increased speeds.

-

Servo Motors: These are closed-loop management methods that mix a motor (usually a brushless DC motor) with a place sensor and a controller. This enables for extremely correct and responsive management of velocity and place, making them important in robotics and high-precision functions. The suggestions mechanism ensures correct positioning and minimizes errors.

-

Linear Motors: In contrast to rotary motors, linear motors produce linear movement straight. They eradicate the necessity for mechanical transmissions, resulting in increased speeds, accelerations, and effectivity. Nevertheless, they’re usually dearer and require specialised design issues.

III. Choosing the Proper Motor:

Selecting the suitable motor for a given utility requires cautious consideration of a number of components:

- Energy necessities: The motor have to be able to delivering the required torque and velocity.

- Working atmosphere: Components like temperature, humidity, and vibration have to be thought of.

- Management necessities: The extent of precision and velocity management wanted will affect the selection of motor sort.

- Value: Balancing efficiency necessities with price range constraints is essential.

- Upkeep necessities: The frequency and complexity of upkeep needs to be thought of.

- Effectivity: Selecting a high-efficiency motor can result in vital vitality financial savings over the motor’s lifespan.

- Measurement and weight: Area constraints might dictate the selection of motor.

IV. Future Tendencies:

The sector of electrical motors is continually evolving. A number of key tendencies are shaping the way forward for motor expertise:

- Elevated effectivity: Analysis continues to give attention to bettering motor effectivity to cut back vitality consumption and environmental affect.

- Improved management methods: Superior management algorithms and sensor applied sciences are enabling extra exact and responsive motor management.

- Integration of energy electronics: The mixing of energy electronics inside motor methods is resulting in extra compact and environment friendly designs.

- Good motors: The incorporation of sensors and communication capabilities is enabling the event of "good" motors that may monitor their very own efficiency and talk with different methods.

- New supplies: The event of latest supplies with improved magnetic properties and thermal conductivity is resulting in extra highly effective and environment friendly motors.

Conclusion:

The number of an acceptable motor is a important side of many engineering designs. This text has offered a complete overview of the varied vary of motor sorts out there, highlighting their key traits, benefits, disadvantages, and typical functions. By understanding the nuances of every motor sort and contemplating the precise necessities of the appliance, engineers and designers can choose the optimum motor to realize desired efficiency, effectivity, and cost-effectiveness. The continued development of motor expertise guarantees much more environment friendly, highly effective, and versatile motors within the years to return, driving innovation throughout a variety of industries.

Closure

Thus, we hope this text has offered invaluable insights into Decoding the Drive: A Complete Information to Motor Sorts and Their Purposes. We respect your consideration to our article. See you in our subsequent article!