Decoding the J-Sort Basis Bolt Weight Chart: A Complete Information

Associated Articles: Decoding the J-Sort Basis Bolt Weight Chart: A Complete Information

Introduction

With enthusiasm, let’s navigate via the intriguing matter associated to Decoding the J-Sort Basis Bolt Weight Chart: A Complete Information. Let’s weave attention-grabbing info and supply contemporary views to the readers.

Desk of Content material

Decoding the J-Sort Basis Bolt Weight Chart: A Complete Information

Basis bolts are crucial elements in development, making certain the safe anchoring of structural parts to their foundations. Among the many numerous sorts, J-type basis bolts stand out resulting from their distinctive design, providing superior load-bearing capabilities and ease of set up in sure purposes. Understanding the burden of those bolts is essential for correct materials estimations, transportation planning, and total undertaking value administration. This text delves into the intricacies of J-type basis bolt weight charts, exploring the elements influencing weight, deciphering chart information, and offering sensible steering for engineers and contractors.

Understanding J-Sort Basis Bolts:

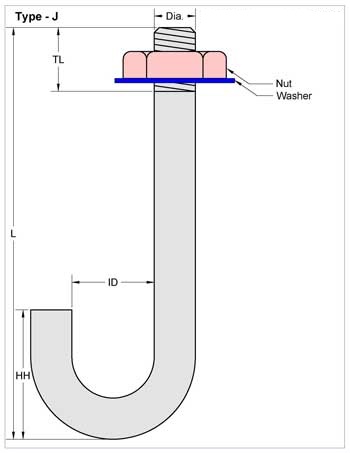

J-type basis bolts, also called J-bolts, are characterised by their distinctive "J" form. This design incorporates a threaded rod with a bent finish, usually that includes a wider, flattened portion designed to be embedded inside the concrete basis. The straight portion of the bolt protrudes above the concrete floor, permitting for the attachment of structural members through nuts and washers. This configuration gives a number of benefits:

- Superior Anchorage: The embedded portion offers glorious anchorage inside the concrete, resisting uplift and lateral forces successfully.

- Simplified Set up: The pre-bent form simplifies the set up course of, decreasing the necessity for on-site bending and making certain constant embedment depth.

- Versatility: J-bolts can be utilized in a variety of purposes, together with anchoring columns, beams, equipment, and different heavy tools.

- Value-Effectiveness: Whereas the preliminary value is perhaps barely larger than easier anchor bolts, the benefit of set up and superior efficiency usually result in total value financial savings.

Components Affecting J-Sort Basis Bolt Weight:

The burden of a J-type basis bolt shouldn’t be a hard and fast worth however slightly will depend on a number of interconnected elements:

- Diameter (d): That is probably the most important issue influencing weight. Bigger diameter bolts have a significantly larger cross-sectional space, resulting in a considerable enhance in weight. Frequent diameters vary from 1/2 inch to 2 inches and even bigger, relying on the applying’s load necessities.

- Size (L): The general size of the bolt, together with each the embedded and protruding parts, instantly impacts the burden. Longer bolts naturally weigh extra. The size is essential for making certain ample embedment depth within the concrete, as inadequate embedment can compromise the bolt’s holding capability.

- Materials: J-bolts are sometimes manufactured from high-strength metal alloys, akin to carbon metal or alloy metal. The particular alloy and its density instantly affect the bolt’s weight. Larger-strength alloys usually have barely larger densities, leading to a touch elevated weight.

- Thread Sort and Pitch: The kind of thread (e.g., coarse or tremendous) and the thread pitch (distance between threads) can subtly affect the burden. Nevertheless, this impact is often minor in comparison with the affect of diameter and size.

- End: Floor remedies like hot-dip galvanizing add a protecting zinc coating, barely rising the general weight. Different finishes, akin to powder coating, may additionally contribute to a minor weight enhance.

Deciphering J-Sort Basis Bolt Weight Charts:

J-type basis bolt weight charts are sometimes introduced in tabular format, organizing information based mostly on the important thing parameters talked about above. A typical chart may embrace columns for:

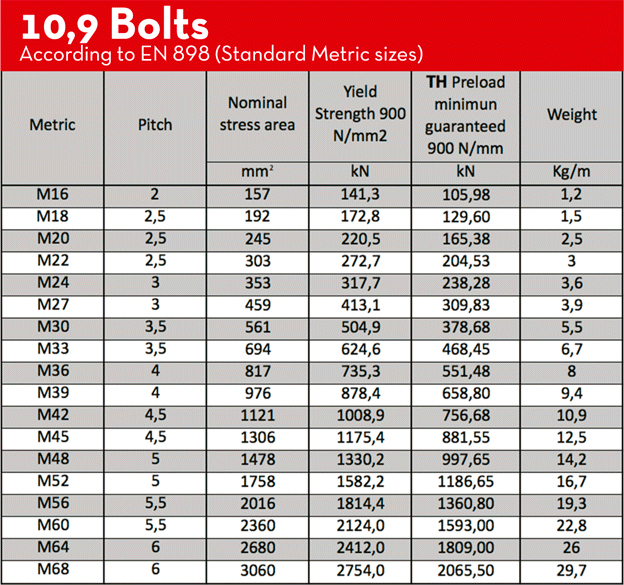

- Bolt Diameter (d): Listed in inches or millimeters.

- Bolt Size (L): Listed in inches or millimeters, specifying the general size from the tip of the embedded portion to the tip of the threaded rod.

- Weight per Bolt: That is often expressed in kilos (lbs) or kilograms (kg). This worth represents the burden of a single bolt with the desired dimensions and materials.

- Materials Grade: Indicating the precise metal alloy used (e.g., ASTM A307, ASTM A36, ASTM F1554). This permits for comparability between bolts of various energy and materials properties.

- Variety of Bolts: Some charts may embrace a column for the overall variety of bolts required for a particular utility. That is significantly helpful for large-scale initiatives.

Utilizing the Weight Chart for Venture Planning:

The burden chart serves as a crucial instrument for numerous facets of undertaking planning:

- Materials Procurement: Correct weight information ensures the right amount of bolts is ordered, minimizing waste and delays.

- Transportation Prices: Figuring out the overall weight of the bolts helps in figuring out applicable transportation strategies and related prices. Heavy shipments may require specialised trucking or different logistical preparations.

- Basis Design: The burden of the bolts, whereas comparatively small in comparison with different basis elements, is taken into account in total basis design calculations, significantly for large-scale buildings.

- Value Estimation: The price of basis bolts is a direct operate of their weight and materials grade. Correct weight information contributes to express value estimations for the complete undertaking.

Past the Weight Chart: Issues for Engineers and Contractors:

Whereas the burden chart offers important info, engineers and contractors should additionally take into account different crucial elements:

- Load Capability: The burden chart does not instantly point out the bolt’s load-bearing capability. This requires separate calculations based mostly on the bolt’s materials properties, diameter, embedment depth, and the anticipated hundreds. Related engineering requirements and codes have to be adopted.

- Corrosion Safety: The setting the place the bolts shall be put in influences the necessity for corrosion safety. Galvanized bolts are sometimes most popular in corrosive environments to increase their service life.

- Set up Strategies: Correct set up strategies are very important to make sure the bolt’s efficient anchorage. This contains applicable drilling, grouting, and tightening procedures.

- High quality Management: Sourcing bolts from respected producers and implementing high quality management checks are essential to make sure the bolts meet the required specs and supply dependable efficiency.

Conclusion:

J-type basis bolt weight charts are invaluable instruments for engineers and contractors concerned in development initiatives. Understanding the elements influencing bolt weight, deciphering chart information appropriately, and contemplating different related elements are important for profitable undertaking planning, execution, and long-term structural integrity. Through the use of the burden chart successfully and adhering to finest practices, professionals can make sure the protected and dependable anchoring of structural parts, contributing to the general stability and longevity of the constructed buildings. All the time seek the advice of related engineering requirements and codes to make sure the right choice and set up of J-type basis bolts for every particular utility.

Closure

Thus, we hope this text has supplied invaluable insights into Decoding the J-Sort Basis Bolt Weight Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!