Decoding the Metal: A Complete Information to Knife Making Metal

Associated Articles: Decoding the Metal: A Complete Information to Knife Making Metal

Introduction

With enthusiasm, let’s navigate by way of the intriguing matter associated to Decoding the Metal: A Complete Information to Knife Making Metal. Let’s weave attention-grabbing info and supply recent views to the readers.

Desk of Content material

Decoding the Metal: A Complete Information to Knife Making Metal

The center of any high quality knife lies in its metal. Choosing the proper metal is an important step in knife making, impacting all the pieces from edge retention and toughness to corrosion resistance and ease of sharpening. This information will delve into the world of knife making steels, offering a complete chart and clarification of varied alloys, their properties, and their suitability for various functions.

Understanding Metal Composition:

Earlier than diving into particular steels, it is important to know the fundamentals of metal composition. Metal is an alloy primarily composed of iron (Fe) and carbon (C). Carbon is the important thing component figuring out the metal’s hardness and energy. Increased carbon content material usually results in better hardness and edge retention however may make the metal extra brittle. Different alloying parts, resembling chromium (Cr), molybdenum (Mo), vanadium (V), tungsten (W), and manganese (Mn), are added to reinforce particular properties. These additions considerably impression the metal’s efficiency, creating a wide selection of choices for knife makers.

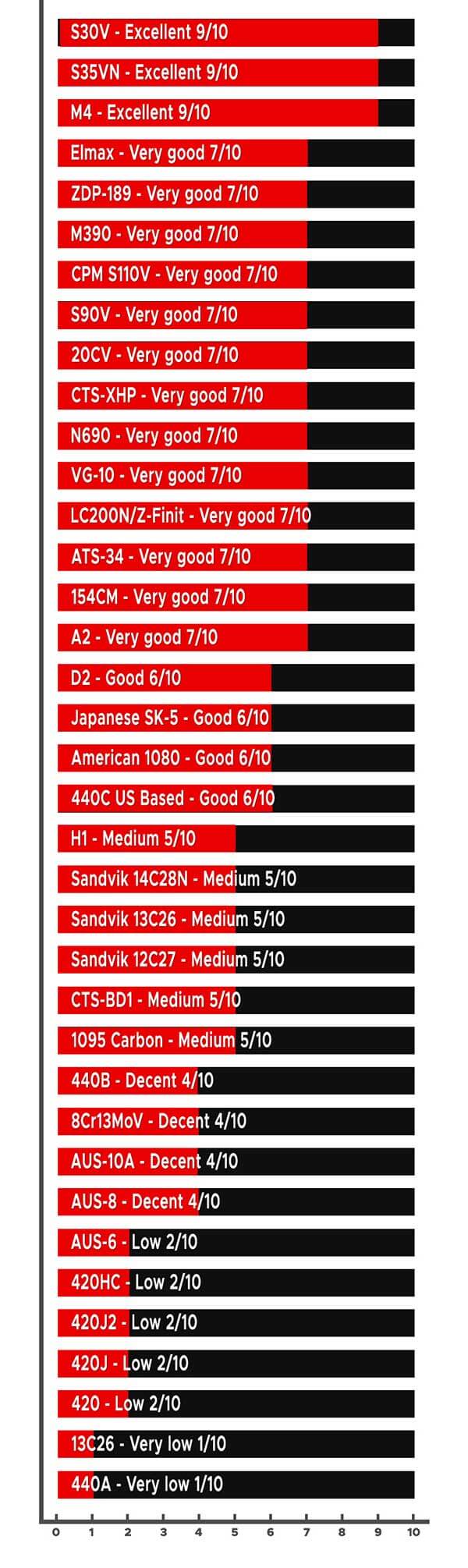

The Knife Making Metal Chart:

The next chart outlines a number of the hottest knife making steels, categorized for readability. Observe that this isn’t an exhaustive checklist, and lots of variations and proprietary blends exist. The properties listed are normal ranges and may fluctuate barely relying on the precise warmth therapy and manufacturing course of.

| Metal Grade | Carbon (%) | Chromium (%) | Vanadium (%) | Molybdenum (%) | Hardness (HRC) | Edge Retention | Toughness | Corrosion Resistance | Utility |

|---|---|---|---|---|---|---|---|---|---|

| Excessive Carbon Steels: | |||||||||

| 1095 | 0.95-1.05 | <1 | <0.1 | <0.1 | 58-62 | Good | Reasonable | Low | Cheap blades, normal goal knives |

| 1084 | 0.80-0.90 | <1 | <0.1 | <0.1 | 55-58 | Good | Reasonable | Low | Normal goal, blades, punches |

| Stainless Steels: | |||||||||

| 440A | 0.65-0.75 | 16-18 | <1 | <1 | 56-58 | Good | Reasonable | Good | Normal goal, kitchen knives |

| 440B | 0.75-0.90 | 16-18 | <1 | <1 | 58-60 | Very Good | Reasonable | Good | Kitchen knives, higher-end normal goal |

| 440C | 0.95-1.20 | 16-18 | <1 | <1 | 60-62 | Glorious | Reasonable | Good | Excessive-end kitchen knives, instruments |

| ATS-34 | 0.7-0.8 | 14-16 | 4-5 | 4-5 | 58-61 | Glorious | Good | Good | Excessive-end knives, searching, tactical |

| 154CM | 1.00-1.10 | 14-16 | 1.0-1.2 | <1 | 60-62 | Glorious | Good | Good | Excessive-end knives, searching, tactical |

| Instrument Steels: | |||||||||

| CPM-154 | 1.05-1.15 | 14-16 | 1.0-1.2 | <1 | 60-62 | Glorious | Good | Good | Excessive-end knives, demanding functions |

| CPM-S30V | 1.40-1.50 | 13-15 | 4-5 | 2-3 | 58-61 | Glorious | Good | Good | Excessive-end knives, demanding functions |

| CPM-S35VN | 1.4-1.5 | 13-15 | 4-5 | 2-3 | 59-61 | Glorious | Good | Good | Excessive-end knives, demanding functions |

| Powder Metallurgy Steels: | |||||||||

| M390 | 1.9-2.0 | 16-18 | 3.5-4.5 | 1.0-1.2 | 60-62 | Distinctive | Good | Glorious | Excessive-end knives, excessive sturdiness |

| S90V | 1.0-1.1 | 14-16 | 1-1.2 | 8-9 | 60-62 | Distinctive | Good | Glorious | Excessive-end knives, excessive sturdiness |

Understanding the Chart Columns:

- Metal Grade: The particular designation of the metal.

- Carbon (%): The share of carbon within the metal, a main determinant of hardness.

- Chromium (%): Will increase corrosion resistance and contributes to hardness.

- Vanadium (%): Strengthens the metal and enhances put on resistance.

- Molybdenum (%): Improves hardenability, toughness, and put on resistance.

- Hardness (HRC): Measured on the Rockwell C scale, indicating the metal’s resistance to indentation. Increased HRC means better hardness.

- Edge Retention: A measure of how effectively the knife holds its sharpness.

- Toughness: The metal’s skill to withstand fracturing below impression.

- Corrosion Resistance: The metal’s resistance to rust and corrosion.

- Utility: Advised makes use of for knives constructed from the metal.

Metal Classes and Their Properties:

The chart categorizes steels into a number of teams primarily based on their properties:

-

Excessive Carbon Steels: These steels are characterised by their excessive carbon content material, leading to glorious hardness and edge retention. Nevertheless, they often supply decrease corrosion resistance and toughness in comparison with stainless steels. 1095 and 1084 are traditional examples, widespread for his or her ease of working and good efficiency for a lot of functions.

-

Stainless Steels: These steels comprise important quantities of chromium, offering superior corrosion resistance. They provide a stability of hardness, toughness, and corrosion resistance, making them appropriate for a variety of knife functions. The 440 collection and ATS-34 signify various grades inside this class. Increased numbers throughout the 440 collection (e.g., 440C) usually point out higher efficiency.

-

Instrument Steels: These steels are designed for distinctive hardness, put on resistance, and edge retention. They’re typically harder to work with however present superior efficiency in demanding functions. CPM-154, CPM-S30V, and CPM-S35VN are examples of premium device steels utilized in high-end knives. The "CPM" prefix signifies that these steels are produced utilizing powder metallurgy, a course of that leads to a extra uniform and refined microstructure.

-

Powder Metallurgy Steels: These steels are manufactured utilizing a powder metallurgy course of, leading to a finer grain construction and improved properties in comparison with conventionally produced steels. They provide distinctive hardness, put on resistance, and toughness, however they’re additionally dearer. M390 and S90V are examples of top-tier powder metallurgy steels utilized in probably the most demanding functions.

Selecting the Proper Metal:

Deciding on the suitable metal relies upon closely on the supposed use of the knife.

-

For on a regular basis kitchen knives: 440A, 440B, or ATS-34 supply a superb stability of efficiency and corrosion resistance.

-

For prime-end kitchen knives or chef’s knives: 154CM, CPM-154, CPM-S30V, and even M390 are glorious selections for distinctive edge retention and sturdiness.

-

For searching knives: ATS-34, 154CM, or CPM-S30V supply a superb mixture of edge retention, toughness, and corrosion resistance.

-

For tactical knives: CPM-S30V, CPM-S35VN, or M390 are glorious selections for his or her distinctive sturdiness and efficiency below stress.

-

For budget-friendly knives: 1095 or 1084 supply good worth for cash, although they require extra care to forestall rust.

Past the Chart:

This chart offers a foundational understanding of widespread knife-making steels. Nevertheless, it is essential to keep in mind that the precise efficiency of a knife relies upon not solely on the metal but additionally on the warmth therapy, grinding, and total craftsmanship. Moreover, many different metal grades exist, and new alloys are always being developed. Researching particular metal grades and their properties is crucial for knowledgeable decision-making in knife making. Consulting with skilled knife makers and researching respected sources is all the time really helpful earlier than choosing a metal on your undertaking. The world of knife making metal is huge and interesting, and understanding its nuances is essential to crafting distinctive blades.

Closure

Thus, we hope this text has offered priceless insights into Decoding the Metal: A Complete Information to Knife Making Metal. We respect your consideration to our article. See you in our subsequent article!