distinction between p chart and c chart

Associated Articles: distinction between p chart and c chart

Introduction

On this auspicious event, we’re delighted to delve into the intriguing matter associated to distinction between p chart and c chart. Let’s weave fascinating data and provide contemporary views to the readers.

Desk of Content material

P-Charts vs. C-Charts: Unveiling the Nuances of Statistical Course of Management for Attribute Information

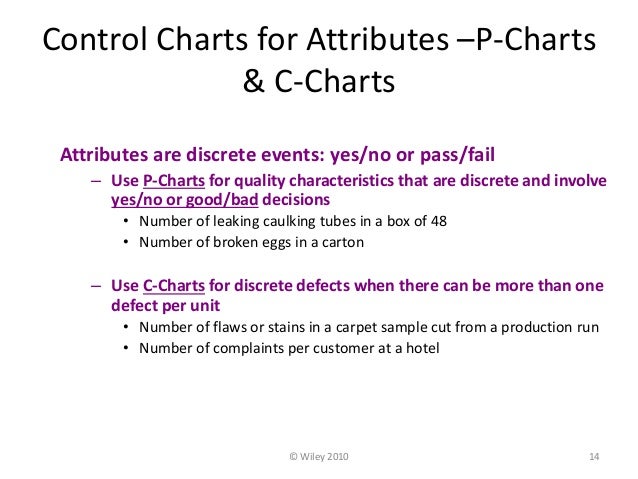

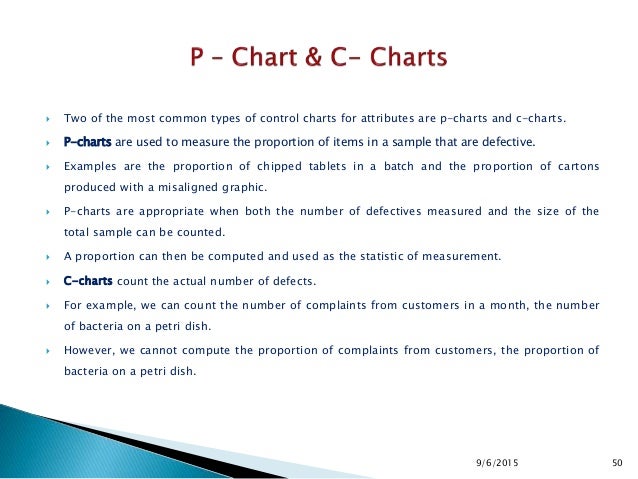

Statistical Course of Management (SPC) is a strong methodology used to watch and enhance processes by figuring out and addressing sources of variation. Inside SPC, management charts play an important function, offering a visible illustration of course of efficiency over time. When coping with attribute knowledge – knowledge that represents the presence or absence of a attribute, relatively than a numerical measurement – two generally employed management charts are the p-chart and the c-chart. Whereas each goal to watch the proportion of nonconforming models, they differ considerably of their utility and the underlying assumptions. Understanding these variations is essential for choosing the suitable chart and precisely deciphering the outcomes.

This text delves into the intricacies of p-charts and c-charts, highlighting their key distinctions, applicable purposes, and the essential issues for his or her efficient implementation.

Understanding Attribute Information

Earlier than diving into the specifics of p-charts and c-charts, it is important to grasp the character of attribute knowledge. Not like variable knowledge, which offers numerical measurements (e.g., weight, size, temperature), attribute knowledge categorizes models as conforming or nonconforming primarily based on whether or not they meet predefined specs. Examples of attribute knowledge embrace:

- Variety of defects in a pattern: Counting the variety of scratches on a painted floor.

- Proportion of faulty models in a pattern: Figuring out the share of defective parts in a batch.

- Presence or absence of a attribute: Checking if a product meets a selected high quality commonplace (e.g., move/fail).

This categorical nature necessitates using specialised management charts like p-charts and c-charts, that are designed to deal with this sort of knowledge successfully.

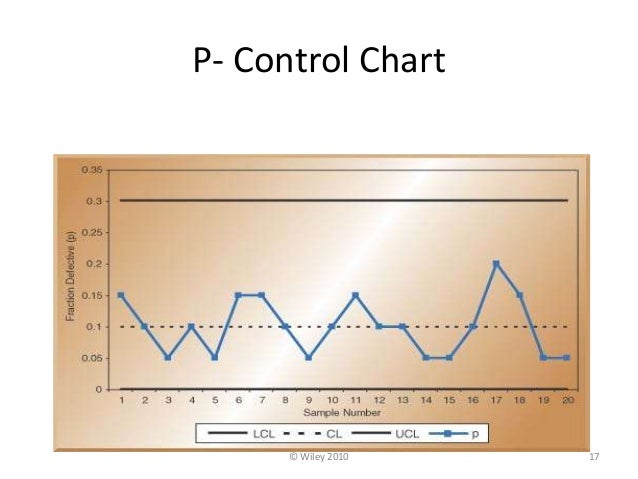

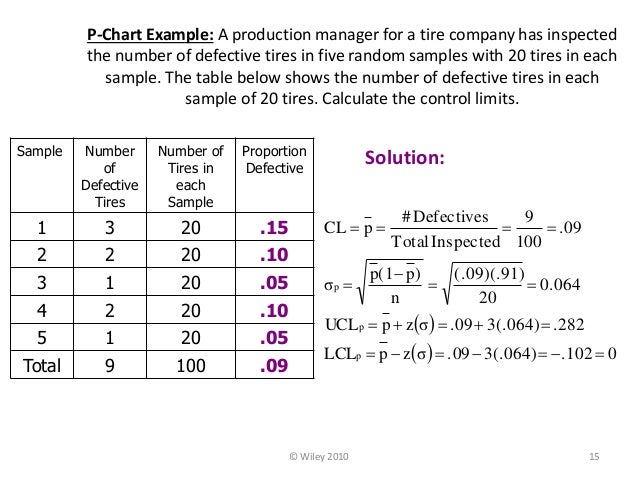

The P-Chart: Monitoring Proportion Nonconforming

A p-chart is used to watch the proportion of nonconforming models in a pattern. It is significantly helpful when the pattern dimension stays comparatively fixed from pattern to pattern. The chart tracks the proportion of defects (p) over time, permitting for the identification of traits or shifts within the course of that may point out a lack of management.

Key Options of a P-Chart:

-

Pattern Measurement: The p-chart requires a constant or almost constant pattern dimension (n) for every subgroup. Important variations in pattern dimension can complicate the evaluation and interpretation.

-

Proportion Nonconforming (p): That is the important thing metric plotted on the chart. It is calculated because the variety of nonconforming models (x) divided by the pattern dimension (n): p = x/n.

-

Management Limits: The higher management restrict (UCL) and decrease management restrict (LCL) are calculated primarily based on the typical proportion nonconforming (p̄) and the pattern dimension (n). These limits outline the appropriate vary of variation for the method. Widespread formulation for calculating these limits are:

- UCL = p̄ + 3√(p̄(1-p̄)/n)

- LCL = p̄ – 3√(p̄(1-p̄)/n) (Notice: LCL is usually set to 0 if the calculated worth is destructive)

-

Middle Line: The middle line represents the typical proportion nonconforming (p̄) calculated from the historic knowledge.

Acceptable Functions of P-Charts:

P-charts are ideally suited to monitoring processes the place:

- The pattern dimension is comparatively fixed.

- The information represents the proportion of nonconforming models in a pattern.

- The method produces a lot of models, permitting for statistically significant samples.

- The target is to watch the general high quality degree of the method.

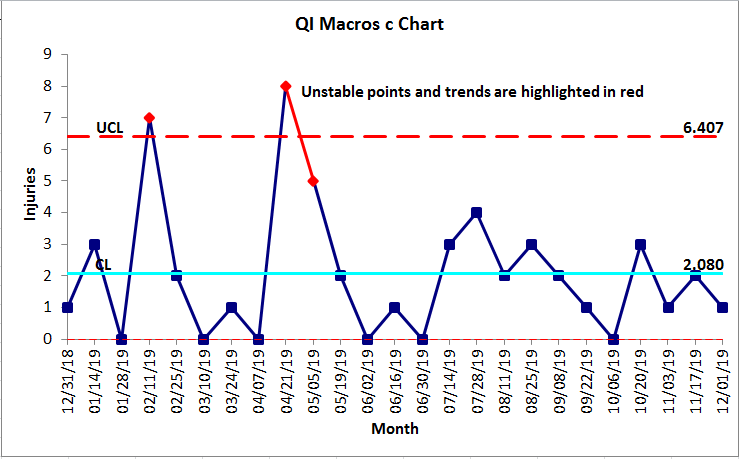

The C-Chart: Monitoring the Variety of Defects

Not like the p-chart, the c-chart displays the variety of defects (c) in a constant-size unit. This unit could be a product, a pattern of fastened dimension, a hard and fast size of fabric, a hard and fast space, or a hard and fast time interval. The important thing distinction is that the pattern dimension is fastened, and the chart tracks the variety of defects, not the proportion.

Key Options of a C-Chart:

-

Fixed Unit Measurement: The c-chart requires a persistently sized unit of inspection. This unit might be a single product, a hard and fast size of fabric, a selected space, or an outlined time interval.

-

Variety of Defects (c): That is the important thing metric plotted on the chart. It represents the full variety of defects noticed throughout the constant-size unit.

-

Management Limits: The management limits are calculated primarily based on the typical variety of defects (c̄) noticed within the historic knowledge. The formulation for the management limits are:

- UCL = c̄ + 3√c̄

- LCL = c̄ – 3√c̄ (Notice: LCL is usually set to 0 if the calculated worth is destructive)

-

Middle Line: The middle line represents the typical variety of defects (c̄) calculated from the historic knowledge.

Acceptable Functions of C-Charts:

C-charts are finest suited to monitoring processes the place:

- The unit of inspection is persistently sized.

- The information represents the variety of defects inside a hard and fast unit.

- The variety of defects per unit is comparatively small in comparison with the unit dimension.

- The target is to watch the defect fee inside an outlined unit.

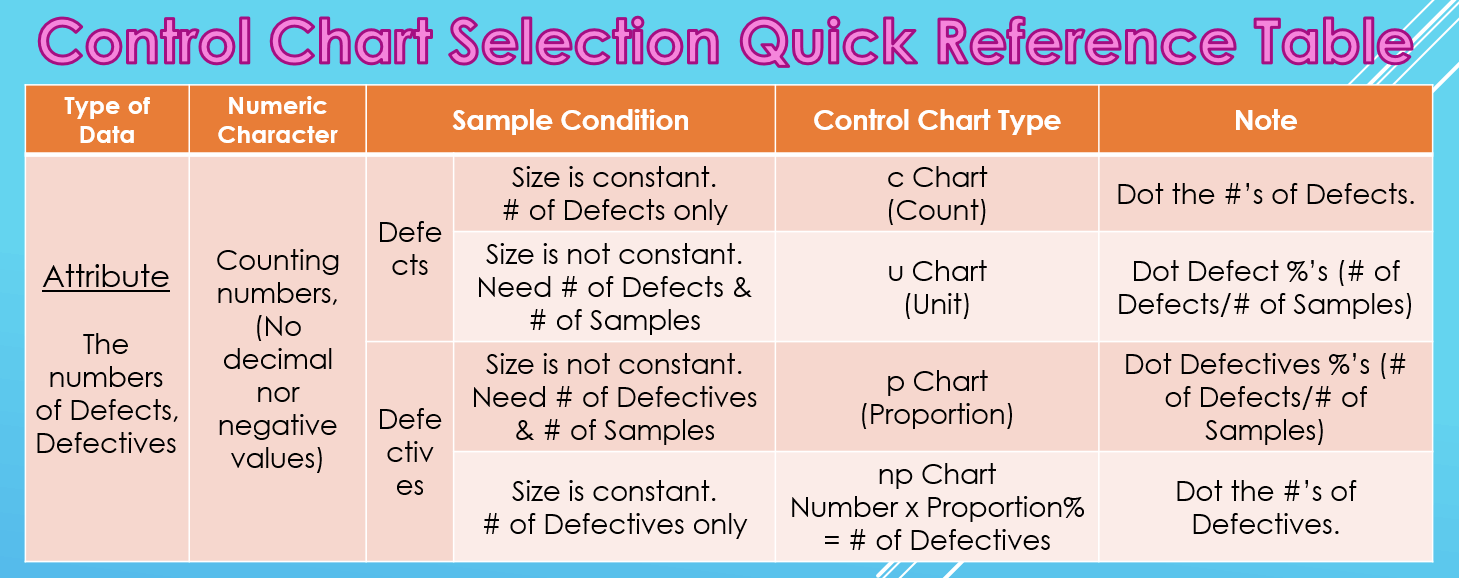

Key Variations between P-Charts and C-Charts:

| Characteristic | P-Chart | C-Chart |

|---|---|---|

| Information Kind | Proportion nonconforming (p) | Variety of defects (c) |

| Pattern Measurement | Variable, however comparatively fixed | Fixed |

| Metric Plotted | Proportion of nonconforming models in a pattern | Variety of defects in a constant-size unit |

| Management Limits | Primarily based on p̄ and n | Primarily based on c̄ |

| Utility | Monitoring proportion of defects in samples | Monitoring variety of defects in a hard and fast unit |

Selecting Between P-Charts and C-Charts:

The selection between a p-chart and a c-chart relies upon solely on the character of the info and the target of the monitoring course of. If the pattern dimension is constant and the main focus is on the proportion of nonconforming models, a p-chart is acceptable. If the unit of inspection is fixed and the main focus is on the variety of defects inside that unit, a c-chart is extra appropriate. Misusing these charts can result in inaccurate interpretations and ineffective course of enchancment efforts.

Past the Fundamentals: Issues for Efficient Implementation

The efficient use of each p-charts and c-charts requires cautious consideration of a number of elements:

- Information Assortment: Correct and constant knowledge assortment is paramount. Set up clear definitions of defects and guarantee constant measurement strategies throughout all samples.

- Pattern Measurement Choice: For p-charts, a sufficiently giant pattern dimension is essential for dependable estimates of the proportion nonconforming. For c-charts, the consistency of the unit dimension is essential.

- Rational Subgrouping: Samples needs to be grouped rationally to replicate the inherent variability throughout the course of. Subgroups needs to be collected in a method that minimizes the variation throughout the subgroup and maximizes the variation between subgroups.

- Interpretation of Management Charts: Understanding the which means of factors outdoors the management limits and patterns throughout the management limits is essential for efficient course of enchancment. Factors outdoors the boundaries recommend assignable causes that want investigation, whereas patterns throughout the limits might point out underlying course of points that require consideration.

- Software program Instruments: Statistical software program packages can significantly simplify the creation and evaluation of p-charts and c-charts. These instruments automate the calculations of management limits and supply visible representations of the info.

Conclusion

P-charts and c-charts are worthwhile instruments for monitoring attribute knowledge in varied processes. By understanding their distinct traits and applicable purposes, practitioners can successfully leverage these charts to establish course of variations, enhance high quality, and obtain better effectivity. The cautious number of the suitable chart, coupled with rigorous knowledge assortment and interpretation, is important for maximizing the advantages of those highly effective statistical course of management methods. Keep in mind that these charts should not standalone options; they need to be built-in right into a broader high quality administration system to attain sustainable course of enchancment.

Closure

Thus, we hope this text has offered worthwhile insights into distinction between p chart and c chart. We hope you discover this text informative and useful. See you in our subsequent article!