Moody Chart Calculator in Excel: A Complete Information to Optimizing Pipeline Design

Associated Articles: Moody Chart Calculator in Excel: A Complete Information to Optimizing Pipeline Design

Introduction

With enthusiasm, let’s navigate by means of the intriguing subject associated to Moody Chart Calculator in Excel: A Complete Information to Optimizing Pipeline Design. Let’s weave attention-grabbing data and supply contemporary views to the readers.

Desk of Content material

Moody Chart Calculator in Excel: A Complete Information to Optimizing Pipeline Design

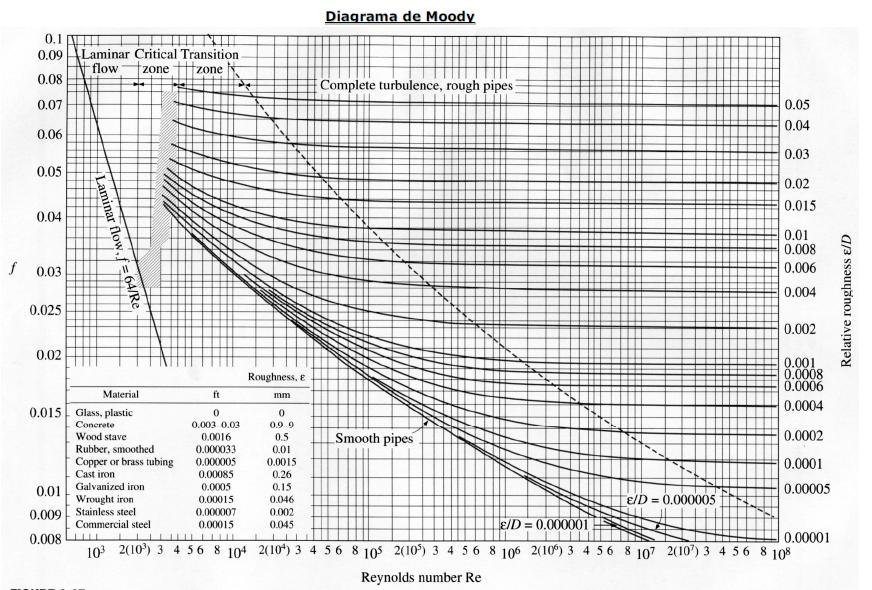

The Moody chart, a graphical illustration of the Darcy-Weisbach friction issue (f) towards the Reynolds quantity (Re) for varied relative roughness (ε/D) values, is a cornerstone of fluid mechanics. It is essential for engineers designing pipelines, figuring out stress drops, and optimizing fluid move. Whereas the chart itself gives a visible understanding, handbook calculations utilizing the Moody chart may be tedious and liable to error. That is the place an Excel-based Moody chart calculator proves invaluable. This text explores the creation and software of such a calculator, offering an in depth understanding of its performance, limitations, and sensible functions.

Understanding the Moody Chart and its Parameters

Earlier than delving into the Excel implementation, let’s revisit the basic parameters concerned:

- Darcy-Weisbach Friction Issue (f): This dimensionless issue represents the resistance to move inside a pipe. A better friction issue signifies higher resistance.

-

Reynolds Quantity (Re): This dimensionless quantity characterizes the move regime – laminar (Re < 2000), transitional (2000 < Re < 4000), or turbulent (Re > 4000). It is outlined as Re = (ρVD)/μ, the place:

- ρ is the fluid density.

- V is the common fluid velocity.

- D is the pipe interior diameter.

- μ is the dynamic viscosity of the fluid.

- Relative Roughness (ε/D): This dimensionless parameter represents the ratio of the pipe’s common roughness (ε) to its interior diameter (D). It accounts for the floor texture of the pipe materials, influencing the friction issue.

The Moody chart graphically interrelates these three parameters. For a given Re and ε/D, the chart permits willpower of the friction issue f.

Constructing a Moody Chart Calculator in Excel

Making a Moody chart calculator in Excel entails a number of steps:

-

Knowledge Enter: Designate cells for inputting the required parameters: fluid density (ρ), dynamic viscosity (μ), pipe interior diameter (D), common fluid velocity (V), and pipe roughness (ε). Use acceptable items (e.g., kg/m³, Pa·s, m, m/s, m).

-

Reynolds Quantity Calculation: In a separate cell, calculate the Reynolds quantity utilizing the method:

Re = (ρ*V*D)/μ. -

Relative Roughness Calculation: Calculate the relative roughness utilizing the method:

ε/D = ε/D. -

Friction Issue Calculation: That is the core of the calculator. A number of approaches exist:

-

Approximation Formulation: A number of empirical formulation approximate the friction issue for various move regimes. The Colebrook-White equation is probably the most correct however requires iterative options. Less complicated approximations, just like the Haaland equation, supply quicker calculations with acceptable accuracy for a lot of functions:

1/√f = -1.8 log10[(ε/(3.7D)) + (6.9/Re)^0.8](Haaland equation) -

Lookup Desk: Create a desk in Excel with pre-calculated friction components for varied Re and ε/D mixtures. Use the

VLOOKUPorINDEXandMATCHfeatures to interpolate the friction issue primarily based on the calculated Re and ε/D values. This methodology is much less correct than direct calculation however avoids iterative options. -

Solver Add-in: For prime accuracy, make the most of Excel’s Solver add-in to iteratively clear up the Colebrook-White equation:

1/√f = -2 log10[(ε/(3.7D) + 2.51/(Re√f))](Colebrook-White equation)

-

-

Output: Show the calculated Reynolds quantity, relative roughness, and friction consider clearly labeled cells.

-

Knowledge Validation: Implement information validation to make sure enter values are inside affordable ranges and items are constant. This prevents errors and improves person expertise.

-

Visible Illustration (Non-obligatory): Think about including a chart visualizing the connection between the calculated parameters and the Moody chart itself. This may be achieved by embedding an image of the Moody chart and highlighting the calculated level.

Selecting the Proper Strategy for Friction Issue Calculation

The selection of methodology for calculating the friction issue will depend on the specified accuracy and computational complexity:

-

Haaland Equation: Gives steadiness between accuracy and computational simplicity. Appropriate for many engineering functions the place excessive precision is not vital.

-

Lookup Desk: Easiest to implement however sacrifices accuracy. Greatest fitted to functions the place pace is prioritized over precision, or for academic functions as an example the Moody chart’s ideas.

-

Colebrook-White Equation (with Solver): Gives probably the most correct outcomes however requires the Solver add-in and iterative calculations. Splendid for conditions demanding excessive precision, reminiscent of vital pipeline design or analysis.

Purposes of the Excel Moody Chart Calculator

The Excel-based Moody chart calculator finds widespread functions in varied engineering disciplines:

-

Pipeline Design: Figuring out the suitable pipe diameter and materials for a given move charge and stress drop.

-

Stress Drop Calculation: Estimating the stress loss alongside a pipeline phase, essential for pump choice and system optimization.

-

Fluid Movement Evaluation: Analyzing the move regime (laminar, turbulent) and its affect on power losses.

-

Course of Engineering: Designing and optimizing fluid transport techniques in chemical, petrochemical, and different course of industries.

-

Hydraulic Programs Design: Calculating head losses in hydraulic techniques, together with water distribution networks and irrigation techniques.

-

Academic Functions: Offering a sensible instrument for college kids to know and apply the ideas of fluid mechanics.

Limitations and Issues

Whereas extraordinarily helpful, the Excel Moody chart calculator has limitations:

-

Accuracy: The accuracy will depend on the chosen methodology for friction issue calculation. Approximation formulation introduce inherent errors.

-

Pipe Geometry: The calculator assumes a round pipe. Modifications are wanted for non-circular geometries.

-

Fluid Properties: Correct fluid properties (density and viscosity) are important for dependable outcomes. These properties can range with temperature and stress, requiring acceptable changes.

-

Non-Newtonian Fluids: The Moody chart and the related equations are primarily legitimate for Newtonian fluids. Modifications are required for non-Newtonian fluids.

-

Pipe Roughness: Correct willpower of pipe roughness is essential. Values can range relying on the pipe materials, age, and situation.

Conclusion

An Excel-based Moody chart calculator is a robust instrument for engineers and college students alike. It streamlines the method of figuring out friction components, enabling environment friendly pipeline design and fluid move evaluation. By understanding the underlying ideas and selecting the suitable calculation methodology, engineers can leverage this instrument to optimize fluid transport techniques and improve their designs. Whereas limitations exist, the advantages of elevated effectivity and accuracy considerably outweigh these drawbacks, making the Excel Moody chart calculator an indispensable asset within the discipline of fluid mechanics. The selection of calculation methodology – Haaland equation, lookup desk, or Colebrook-White equation with Solver – needs to be guided by the specified accuracy and computational assets accessible, guaranteeing the optimum steadiness between precision and effectivity for every particular software.

Closure

Thus, we hope this text has supplied beneficial insights into Moody Chart Calculator in Excel: A Complete Information to Optimizing Pipeline Design. We respect your consideration to our article. See you in our subsequent article!